[ad_1]

Nissan licenses lithium-ion battery technology to APB Corporation

Advanced technology will help consumers use low-cost and renewable energy more effectively

YOKOHAMA, Japan – Nissan has licensed an advanced technology to APB Corporation that will allow mass production of lower-cost, safer lithium-ion batteries with increased charging capacity.

Backed by investment from major companies, Tokyo-based APB plans to build a factory in Japan that will use Nissan’s technology to make all-polymer batteries for storage use.

All-polymer batteries are said to be the next generation of lithium-ion batteries. Nissan’s technology, known as bipolar structure all-polymer battery technology, will help consumers and communities to more effectively use low-cost or renewable energy at a lower initial cost.

“We believe the widespread adoption of this technology will contribute to fulfilling the U.N.’s sustainable development goals and help realize a sustainable, low-carbon society,” said Hideki Kimata, vice president of the corporate strategy and business development division at Nissan.

Nissan began researching and developing lithium-ion batteries in the early 1990s. In 1997, Nissan launched the Prairie Joy EV and became a pioneer in installing lithium-ion batteries in commercial electric cars. Since then, Nissan has continued to research core technologies and pursue innovation in the field of EV batteries.

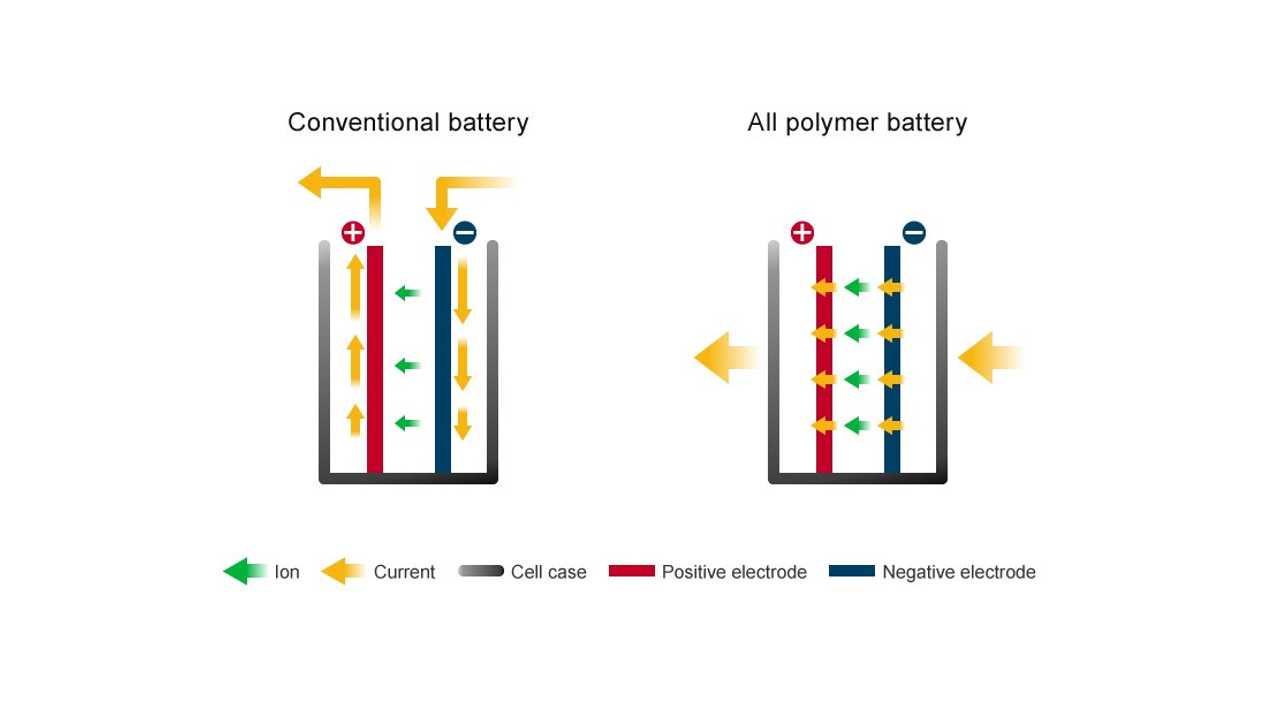

Bipolar structure all-polymer battery technology: overview

In an all-polymer battery with a bipolar structure, the liquid electrolyte and metal electrodes used in conventional batteries are replaced with polymers. The front and back of the battery cell are made of a polymer current collector. The front and back each has a negative or positive polarity and forms part of the battery case. By stacking a number of these cells together, an assembled battery with a bipolar structure is created.

The technology increases charging capacity relative to battery volume, while also enhancing safety by replacing liquid electrolytes with polymers. The simplified structure also lowers cost.

Application to stationary batteries

Mainstream use of stationary batteries with this technology will help individual customers make effective use of low-cost electricity, such as renewable energy from solar panels or electricity purchased from the grid during off-peak hours, with a smaller initial investment.

As a result, local communities can limit electricity use during peak hours and use power in a more stable and efficient manner. This reduces the risk of blackouts due to disasters or technical failures, and can contribute to a safer, cleaner energy supply.

[ad_2]

Source link

0 Comments